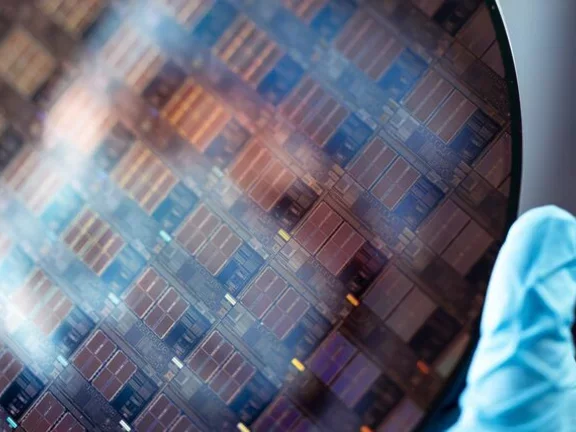

Digital technologies have grown exponentially over the past decade, revolutionizing every industry on the planet and the way the world works and connects. At the basis of these technologies, semiconductors are the building blocks for producing data processors, memories, displays and photovoltaic cells that equip our computers, internet servers, smartphones, etc. Air Liquide's Electronics business line designs and supplies technological solutions based on very high purity gas and advanced materials, which help to produce semiconductors that are ever more performant and energy efficient, thus helping to meet the climate challenge.

Collaboration and inventiveness

Products manufactured by Electronics customers respond to increasingly challenging consumer demands for improved mobility, connectivity, computing power and energy consumption. These technological advances are made possible thanks to the innovative materials and gases used in semiconductors production.

In response, many of the advanced materials developed by Air Liquide have gone on to become industry standards, as a result of the Group’s early engagement with its customers. When new challenges arise, inventive answers are required. Air Liquide materials scientists and engineers turn these design challenges into solutions through innovation.

“Working hand in hand with its customers every step of the way, Air Liquide invents the advanced solutions they need to accelerate innovation from the research laboratory to full-scale fabrication.

”

Guillaume Cottet

Vice President, Electronics World Business Line at Air Liquide

Our products and services offer

Carrier gases

Advanced materials

Specialty materials

Equipment & Installations

We also supply equipment for the distribution of gas and chemical products and install them at our customers’ facilities.

Services

Customers rely on our expertise for the daily management of gases and chemical products on their sites, as well as to provide cutting-edge analytical services to continuously improve their production processes.

Labelled among 1,000 efficient, clean and profitable solutions by the Solar Impulse Foundation

The environmental benefits of the enScribe™ range

Among the Group’s latest innovations are enScribe™ range of advanced etching materials that facilitate the manufacturing of complex 3D memory structures, while greatly reducing the environmental impact. By adopting enScribe™, a major semiconductor manufacturer is reducing industry-wide carbon equivalent emissions by 1%.

In 2022, the use of enScribe™ range materials has made it possible to avoid the emission of 133,000 tonnes of CO2.