Safety

A fundamental value

Safety is a fundamental value. It is an integral part of Air Liquide’s operational excellence and culture. The Group is committed to effectively reducing the exposure of its employees, subcontractors, customers, suppliers and local communities to professional and industrial risks in all circumstances.

One ambition: zero accident

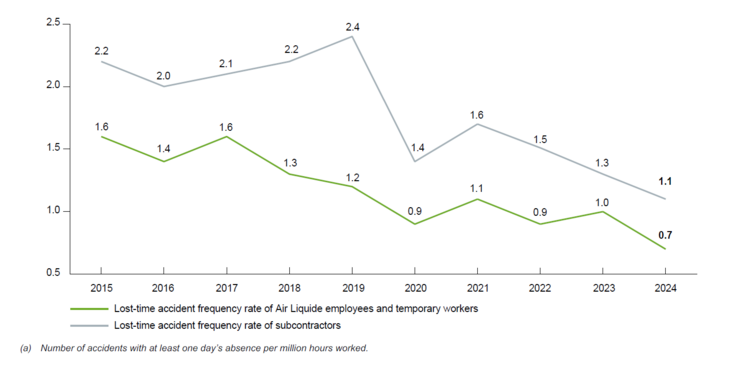

Lost-time accident frequency rate, a key safety performance indicator, has demonstrated a consistent improvement over the past twenty years for both Air Liquide employees (including temporary workers) and subcontractors, as shown below.

The sharp drop in 2020 compared to 2019 is attributed to covid-19 pandemic lockdowns, while the slight increase in 2021, driven by a strong activity rebound, remained below 2019 levels.

Notably, in 2024, the Group achieved its lowest ever lost-time accident frequency rate for both employees and subcontractors.

The positive trend in the frequency rate underscores the increasing maturity of the teams regarding safety, as well as the deepening of the Group safety culture. At the core of this progress lies the understanding that safety is both a collective commitment and an individual responsibility. Air Liquide is committed to 'zero accidents' ambition, fueled by unwavering dedication, demonstrable actions, and relentless vigilance.

Lost-time accident frequency rate trend among Air Liquide employees and subcontractors

Safety actions: three axes

Safety of individuals

Ambitions and objectives are only valuable if they are understood and shared by all stakeholders. To strengthen the Group safety culture, Air Liquide has developed a common set of vital safety rules. These rules, which have been developed on the basis of numerous lessons learned, strengthen prevention and safety in the workplace. Non compliance with one of these rules by anyone working for Air Liquide can lead to a warning or even sanctions.

Every person working for Air Liquide, whether an employee or a subcontractor, must know the rules, apply them and always intervene if there is a risk of dangerous behavior or conditions. This is how Air Liquide makes progress and decreases its accident and incident frequency rates year after year.

A fundamental value for Air Liquide

To address daily safety issues, on-site safety meetings are held regularly between employees and their managers. In addition, it is recommended that each entity conduct monthly safety meetings for broader discussions.

To maintain safety awareness, Air Liquide publishes a monthly internal HSE newsletter. It features safety topics, showcases good practices and entity initiatives, and provides feedback on safety events to promote learning and prevent recurrence. These newsletter elements are then discussed locally between employees and managers.

Road safety

Each year, delivery vehicles, sales staff and technicians travel hundreds of millions of kilometers. Non-compliance with traffic regulations or the lack of regular maintenance of vehicles would expose drivers and third parties to increased risks of accidents.

The Group is working on the rapid deployment of onboard technologies in trucks and vehicles of the Air Liquide fleet to prevent fatigue and distraction.

Furthermore, Air Liquide regularly organizes exchange and capitalization days on transport safety with its partners.

A program adapted to the Group's businesses

Process safety

Process safety addresses risks relating to industrial facilities from production to product implementation. It draws on Air Liquide’s Industrial Management System (IMS), which applies to all activities. Launched in 2005, the IMS has profoundly changed the way Air Liquide organizes and carries out operational activities.

Thanks to employees’ commitment to safety, respect for the environment and reliability, this system helps strive towards operational excellence. Its implementation is regularly assessed by specific IMS internal audits.

To facilitate proactive learning after a major event at a site, rapid feedback is conducted to share lessons and prevent similar incidents from happening elsewhere in the Group. Based on these lessons, relevant IMS documents are reviewed and updated to reflect best practices.

Our Industrial Management System (IMS)