How can we help limit global warming?

Toward a low-carbon industry

Published on May 28, 2020

5 minutes

As global warming is a critical concern, Air Liquide has decided to take action. First of all, the Group has made an ambitious commitment to reduce the carbon intensity of its own activities, driven by innovative projects. Air Liquide is also increasing its initiatives worldwide with customers and partners.

Limiting global warming in line with the 2015 Paris Agreement requires fast unprecedented transformation.

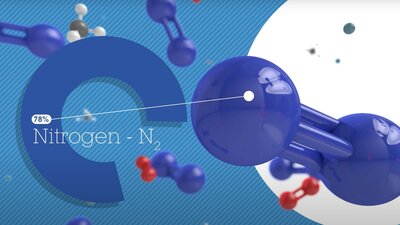

According to the Intergovernmental Panel on Climate Change (IPCC), to achieve carbon neutrality and contain climate deregulation by 2050, industry as well as other sectors (energy, transport, agriculture, etc.) will need to drastically reduce CO2 emissions. As a responsible company, Air Liquide has long made efforts to protect the planet. At the end of 2018, the Group announced the most ambitious Climate objectives of its sector, committing to a 30% reduction in the carbon intensity of its activities by 2025, as compared to 2015. Air Liquide also intends to contribute globally to a more sustainable world by helping its industrial customers reduce their carbon emissions and by developing new technologies and skills to support their low-carbon transition. Its recent investments in low-carbon hydrogen and biomethane demonstrate this commitment.

Acting on its own operations

Air Liquide has started by reducing its own environmental footprint, mainly through clean manufacturing in compliance with the highest standards, by lowering the electricity consumption of its industrial processes and by reducing the carbon intensity of its factories and equipment. The Group’s commitments are demonstrated in several projects initiated in 2019. Air Liquide has contributed to the development of a windfarm in Texas to supply its industrial gas production plants with renewable energy, avoiding 1.5 million tons of CO2 emissions for the duration of the agreement. The Group is also drastically reducing its carbon emissions by investing in new production units and shutting down its older, energy-intensive facilities. This is particularly the case in Russia and the United States, where Air Liquide is building leading-edge air separation units (ASU) to supply its customers, Severstal and Methanex, with the help of sustainable, highperformance solutions. Similarly, the Group is building a world-scale latest-generation hydrogen production plant at the Tabangao refinery in the Philippines. Owned and operated by Air Liquide, it will be paired with a capture and liquefaction unit for CO2 initial discharge, which could then be directed to other uses to reduce direct carbon emissions

Supporting the energy transition in industry

In addition to these efforts are several innovative initiatives to help manufacturers reduce their environmental footprint and move toward a low-carbon future. The Group is testing several solutions with its partners, and around 30 projects are likely to be implemented in the next five years.

Air Liquide is already working with ArcelorMittal on a pilot scheme for capturing and recycling carbon emissions in steel manufacturing. This involves filtering blast furnace waste, using a technical solution developed by Air Liquide. In this way, the ArcelorMittal steelworks in Ghent, Belgium, will become Europe’s first bioethanol production site to use waste gas from steel manufacturing.

In addition in the steel industry, Air Liquide and thyssenkrupp Steel have together launched a pioneering project: for the first time, hydrogen will be injected on a large scale to partly replace the coal used in the blast furnace during steel production. After full-scale deployment at its Duisburg plant in Germany, thyssenkrupp Steel is targeting a 20% reduction in carbon emissions from the steelmaking process. As CO2 emissions remain a growing concern for industrial companies, Air Liquide has also joined Northern Lights, a full-scale carbon capture and storage (CSS) project on the Norwegian continental shelf. Handling large volumes of emissions, CSS offers an effective way to decarbonize industry. The Northern Lights project could become the world’s first storage facility to receive manufacturing gas waste from different European countries.

Jean-Baptiste Salles

Vice President Strategic Customers and Business Model at Air Liquide’s Large Industries business line

A sustainable future in the shipping and transportation industry

Likewise, the maritime industry is facing the issue of greenhouse gas emissions. This sector represents approximately 3%1 of total CO2 emissions worldwide. A number of solutions are being introduced to reduce this footprint and Air Liquide is playing an active role with its Turbo-Brayton technology.

Developed over the past decade by Air Liquide, the TurboBrayton technology has proven its reliability in day-to-day use and met with encouraging success in liquified natural gas (LNG) shipping. This innovation, which is implemented on LNG ships, prevents methane evaporation during transport through reliquefaction. This offers a real advantage over classic gas capture solutions.

The potential applications are numerous, both in shipping and for liquifying biogas from household or agricultural waste methanization facilities.

Approximately €480 M: the cumulative capital expenditure for the 2014-2019 period in biomethane and hydrogen mobility

Another example is biomethane. Air Liquide is pursuing strong growth in this promising production market. The Group owns 18 biomethane production units worldwide, representing an annual capacity of 1.1 TWh. This recent business offers strong potential, especially for customers wanting to convert their vehicle fleet to low-carbon energy. Biomethane offers transporters a 90% reduction in CO2 emissions and an 85% reduction in fine particles. In addition to clean mobility, biomethane naturally has its place in the energy mix and an important role to play in the energy transition. Finally, a major investment in producing carbon-free hydrogen in Canada (see p. 81) will help supply low-carbon hydrogen to the growing mobility market in North America.

Given its strong commitment to reducing its own environmental footprint, the Group is constantly extending its ambition to its industrial partners, who are increasingly concerned about limiting their greenhouse gas emissions and successfully exploring promising markets. In this way, Air Liquide is anticipating and building a more sustainable industry.

Learn more about our 2019 annual report by clicking the link below :