Safety

A fundamental value

Safety is a fundamental value. It is an integral part of Air Liquide’s operational excellence and culture. The Group is committed to efficiently and under all circumstances reducing the exposure of its employees, customers, subcontractors, suppliers and local communities to professional and industrial risks.

One ambition: zero accident

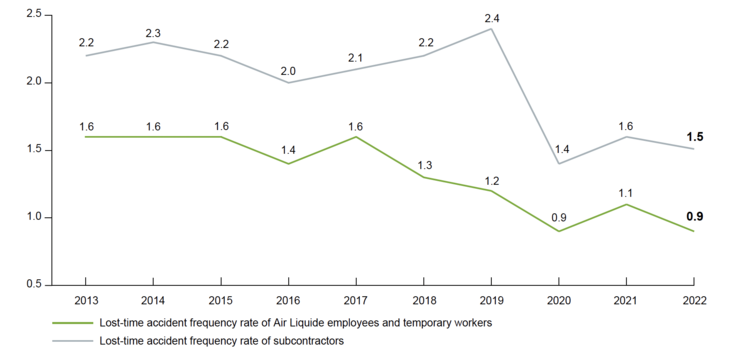

The lost-time accident frequency rate of Air Liquide employees is a safety performance review indicator. As shown in the chart below, this frequency rate has gradually improved over the past twenty years. A sharp drop was observed in 2020 compared to 2019 linked to the different periods of lockdown due to the covid-19 pandemic. A slight increase appears in 2021 related to the strong pick-up in activity but it remains below the frequency rate of 2019, which was the lowest in 20 years. The evolution of the frequency rate highlights the steady progress in the maturity of teams on the subject of safety as well as the development of a safety culture within the Group.

Frequency of accidentsa,b

Safety actions: three axes

Safety of individuals

The Group has drawn up 12 “Life-Saving Rules” on which there is no compromise. Given their importance, non-compliance with one of these rules by anyone working for Air Liquide can lead to a warning, or even sanctions.

On site, safety meetings are organized on a regular basis between employees and their managers to discuss the various safety issues at the heart of their daily work. In addition, it is recommended that each entity organize a monthly safety meeting.

Every month, Air Liquide publishes an internal HSE (Health, Safety, Environment) newsletter to present a safety topic to maintain vigilance, share good practices and initiatives from certain entities, and feedback on safety events to share lessons learned and prevent their recurrence. Elements of this newsletter are then taken up locally and discussed between employees and their managers.

A fundamental value for Air Liquide

Road safety

The Group is working on the rapid deployment of new onboard technologies in trucks and vehicles of the Air Liquide fleet. For instance, cameras can detect driver fatigue and distraction, help change driving habits when necessary, and provide visibility of the vehicle’s surroundings.

Air Liquide regularly organizes exchange and capitalization days on transport safety with its partners.

Special events are regularly organized to recognize road safety performance and promote the sharing of good practices among subsidiaries.

A program adapted to the Group's businesses

Process safety

Since its launch 15 years ago, the IMS has significantly changed and improved the way in which industrial activities are managed. Thanks to employees’ commitment to safety, respect for the environment and reliability, this system helps strive towards operational excellence. Its implementation is regularly assessed by specific IMS internal audits.

The technical standards are regularly reviewed and updated to clarify aspects and to take into account new data.

Rapidly after a major event at a site, feedback is organized to share lessons learned and prevent this from happening elsewhere in the Group. Reference IMS documents are then reviewed as necessary in the light of lessons learned.

Our Industrial Management System (IMS)