China: discovering the new state-of-the-art and more sustainable manufacturing site

Published on August 02, 2023

2 minutes

Air Liquide recently inaugurated its new state-of-the-art manufacturing center in Penglai, Yantai Shandong Province, in China. This is the new base for Air Liquide’s industrial units manufacturing capabilities in China, as well as for our subsidiary Cryolor, which will manufacture high performance liquid hydrogen equipment for the Asian mobility market.

The relocation of facilities from Hangzhou to Yantai was an opportunity for the Group’s Engineering & Construction teams to rethink how they wanted to shape Air Liquide manufacturing capabilities in the country, in light of the Group’s strategy and the challenges in terms of environment and industrial competitiveness.

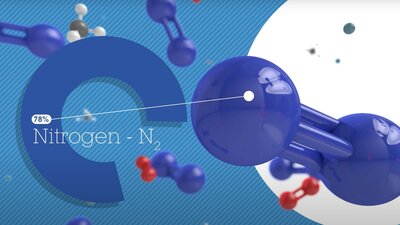

The new manufacturing site includes a sustainable workshop, which notably produces state-of-the-art energy saving air separation units, as well as hydrogen production units. Strategically located on a coastal city with a strong industrial foundation, a solid supply chain and an extensive transportation network, this site will contribute to creating a solid base for the Group’s development not only in China, but also in Asia.

Alongside the Cryogenic Technologies Center in Vitry-sur-Seine, France, and the manufacturing center in Ras Al-Khaimah, United Arab Emirates, the Yantai manufacturing center enables the Group to offer a more diversified portfolio of solutions and services to support the Group’s growth. Thanks to these production capacities, new technologies can be developed faster and turned into concrete industrial projects, particularly those of greater scale and complexity.

"Our manufacturing center in Yantai is a first-of-its-kind. Sustainable and equipped with advanced fabrication capabilities, it is strategically located with direct transport access to several seaports. With these brand new manufacturing capabilities, we will be able to contribute to the transformation of many industries in China and beyond by providing our customers with efficient technologies and executing and delivering complex industrial projects."

Philippe Merino, Group Vice President supervising Engineering & Construction at Air Liquide

This new workshop will also contribute to sustainability improvements designed to reduce carbon footprint such as powering the site with electricity produced by photovoltaic panels, forklifts replaced with electric drives and the set-up of an optimized manufacturing process to maximize recycling.

Find out more in this video: