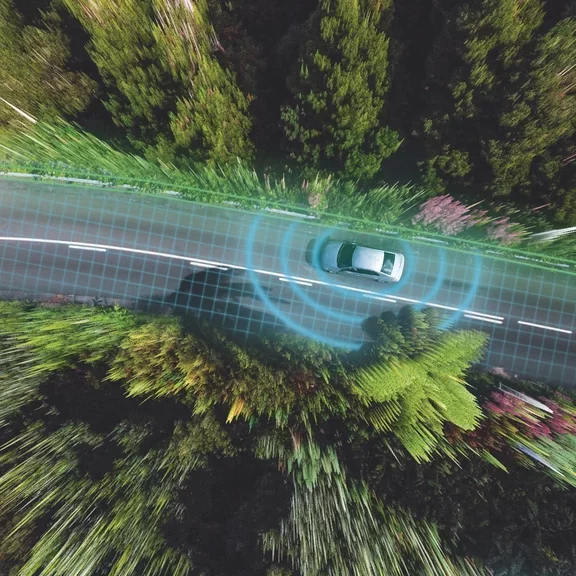

Semiconductors lie at the heart of the digital revolution that is profoundly transforming society. In the ultra-competitive electronics sector, the innovation race encourages the design of increasingly smaller and more powerful components, all while reducing their environmental impact. As a strategic partner to major electronic customers, Air Liquide supports their geographic expansion and helps them face technological challenges, from supplying advanced materials to relocating production units.

157K metric ton of CO₂ emissions avoided in the electronics industry thanks to Air Liquide's enScribe™ solutions in 2021

100% of latest-generation smartphones contain chips, memory, sensors and displays made with Air Liquide's gases and advanced materials

Foster

“We offer a unique range of solutions and advanced materials for the electronics sector backed by the best innovation capability in the industry.

”

Christian Dussarrat

Electronics R&D Program and Scientific Director, Tokyo Innovation Campus, Air Liquide

What role does Air Liquide play in the electronics industry?

As society becomes increasingly digital, the electronics industry is faced with growing demands for increased performance and production of semiconductors. Air Liquide helps the industry by providing the ultra-pure gases and innovative materials necessary for manufacturing chips. The Group’s innovation capacity facilitates the development and manufacturing of the highest-quality, fastest and most powerful nanoscale devices.

What challenges are electronics players facing?

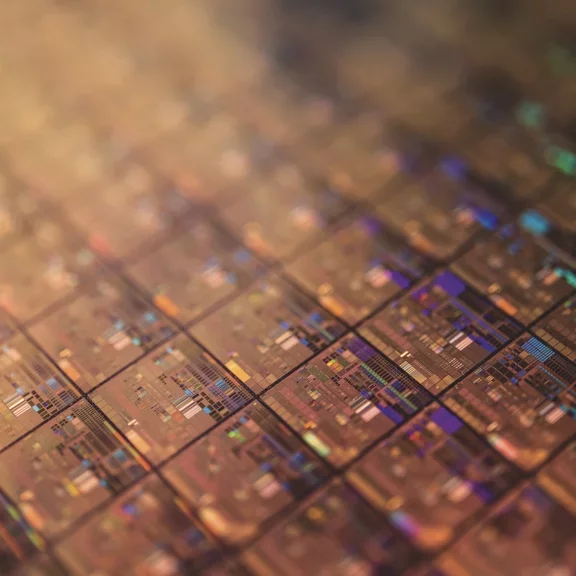

In roughly 15 years, the size of silicon transistors has already decreased from 65 to 5 nanometers. At this scale, flawless quality, product stability, safety and reliability are critical, which is why the electronics industry has specific and very stringent quality requirements for all gases and chemicals supplied to its production plants. In addition to these technological challenges, the industry is also committed to producing semiconductors with smaller environmental footprints, to contribute to low-carbon computing.

How is Air Liquide supporting customers to meet these challenges?

We are driven by our innovative mindset. Since the early 2000s, we have been working on materials called precursors, which deliver specific tailored solutions to customers in the memory and logic segments. More recently, enScribe™ range materials allow etching at a nanoscale with a minimized environmental impact. Over the years, we have ramped up our expertise and now we offer a unique portfolio of solutions and advanced materials backed by the best innovation capability in the industry.

“Our product portfolio is simply the most comprehensive on the market, from ultra-pure carrier gases to novel advanced materials.

”

Ken Liu

Strategic Account Director, Electronics activity at Air Liquide, Taiwan Island

In 2021, Air Liquide signed new contracts with a key Taiwanese electronics player. Can you tell us more?

Air Liquide’s global presence and its unique product portfolio make it an attractive partner to electronics leaders around the world. We are proud to have signed new contracts with a key Taiwanese customer who is taking its geographical expansion up a notch. This customer will be opening a new manufacturing site in Arizona, U.S., with a monthly capacity of 20,000 wafers1, and we will be supplying ultra high purity hydrogen, helium, and carbon dioxide to this facility. We are also in talks with them to partner on further expansion in Taiwan Island and Japan.

How does Air Liquide make the difference from its competitors in the electronics sector?

When it comes to overseas expansion, semiconductor manufacturers want to partner with suppliers they know and trust. We have been supporting this customer and most of the key electronics players for years. They are reassured by our international presence and ability to provide a single customer interface anywhere in the world. Additionally, our product portfolio is simply the most comprehensive on the market, from ultra-pure carrier gases to novel advanced materials.

There is currently strong demand for semiconductors, but an uncertain outlook in areas such as supply chains and international trade. Which challenges is Air Liquide facing as it supports customers expansion?

Sustaining the rapid growth of the industry is not easy. Our expertise and proximity with our customers around the world promote optimal responsiveness and strict quality control. Throughout the Covid-19 pandemic, we didn’t have a single supply chain interruption. Our locations in key electronics hubs like Japan and China also allow us to secure the most cutting-edge solutions for our customers and to support them in their relocation and expansion plans.

Achieve

Invent

The acceleration of the digital transformation both inspires and tests the limits of the electronics industry. Air Liquide is leveraging its rich expertise, innovation capability and global presence to help industry leaders meet their challenges and make the most advanced technologies a reality in everyone’s daily life.