Facilitating professional trade development for young people

Published on December 15, 2020

3 minutes

As several regions of the world, including the United States, are facing a shortage of welders, Air Liquide’s U.S. subsidiary Airgas has expanded its training program. The goal? To help high school technology teachers and students learn new and advanced welding skills. One of the 29 initiatives supported nationwide by Airgas has reached 70 teachers in 12 high schools in Kansas. They have benefited from the expertise of Airgas specialists and equipment donations in this initiative that builds bridges between education and industry.

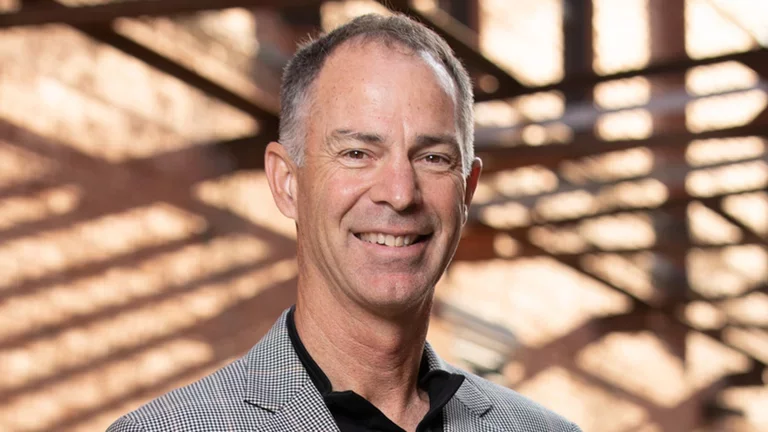

Brian Blackwood, Area Vice President, Airgas Mid-South

What does the Airgas training program in your area involve?

The goal is to give Kansas teachers basic welding and cutting skills, so in turn they can encourage students to consider a career in welding, a job with excellent prospects. The program connects teachers and students in technical schools with industry partners to the benefit of both sides.

What is its objective?

There is an ongoing shortage of welders in the U.S. To date, our Kansas program has allowed 70 teachers to introduce the welding profession to a total of 330 students. If each of the 70 teachers we’ve trained results in just one of these students enrolling in technical college, we’ll have supported 70 trainee welders in their career choice.

What is your motivation?

To provide a level of training to teachers that they would not otherwise receive, and to give a hand up to students by offering them a lifetime skill that they can use anywhere. It's very satisfying for all of us Airgas volunteers to feel like we’re making a difference.

Elizabeth Meyer, Agricultural Education Instructor, Sublette High School, Kansas

Why did you choose to participate in this welding training program?

It came highly recommended by colleagues who had attended last summer. I wanted to further develop my skills in this area, as well as gain from the expertise of industry specialists.

How has it helped you in your professional career?

The one-on-one interactions, classroom instruction and hands-on lab work made me more equipped to demonstrate welding practices to my students and help them produce quality welds and products. The experience also gave me insight into the industry.

What is the impact of the program?

Aside from the time they invested in us, the Airgas instructors offered a variety of resources for continued support, including putting us in contact with the nearest branches so we can remain connected throughout the year. But most importantly, they provided us with the most relevant information to support and prepare our students seeking employment in the industry.

Welding joins workpieces, usually metals. Cutting is used to separate pieces of metal sheets, structures and pipes. These processes require specific gases which have been at the heart of Air Liquide’s offers for over 100 years. In addition to welding and cutting gases, Air Liquide also offers a wide range of handling and welding equipment.

Airgas offer

In the United States, the Group can rely on its Airgas subsidiary, acquired in 2016, to support its welding customers on the other side of the Atlantic. Airgas experts evaluate the processes used by customers to guide them to the right products and equipment, always with a view to improving their performance. Airgas also offers complete supply chain management for gases as well as safety and welding equipment.