Industry: when proximity leads to innovation and agility

Published on July 21, 2021

6 minutes

The health crisis has put pressure on production and logistics chains in many sectors. Air Liquide supports manufacturers in their quest for agility, competitiveness and sustainable solutions thanks to its unique strengths: technological expertise, in-depth knowledge of customer processes, its presence at the heart of local economies… And its ability to innovate relentlessly.

A privileged position to anticipate trends

Serving more than 2 million customers around the world, from craftsmen to SMEs and large companies, Air Liquide contributes to nearly every sector of the economy: food, pharmaceuticals, energy, chemicals, automotive, aeronautics and more. The Group is at the forefront of detecting market changes and anticipating the needs that will transform industrial production methods. It is constantly investing to support its customers in their geographical development while offering them innovative solutions that improve the industrial and environmental performance of their processes. This dynamic is reflected in the signing of several long-term contracts in 2020 with major industrial players in mature economies (United States, Europe) and developing economies (China, Russia).

Constantly adapting to customer needs

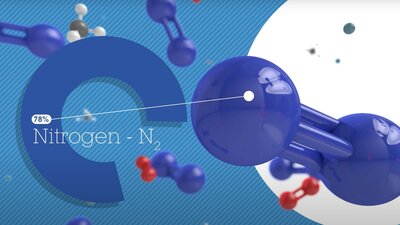

Air Liquide's key assets for advancing industry are its close proximity to its customers and its in-depth knowledge of their industrial processes, which enables it to maximize the full potential of the molecules it supplies and to design innovative equipment. Indeed, the Group is constantly transforming itself to better understand and meet the needs of its customers and respond to them more effectively, even in difficult conditions. For example, SRF, a customer in India specializing in technical textiles and packaging films, wants to become autonomous in its supply and have greater flexibility. Two advantages of Air Liquide’s on-site gas production solution that met the customer’s expectations. In 2020, despite the many restrictions resulting from the health crisis, multidisciplinary teams worked together on-site and remotely to successfully install and commission a nitrogen production unit at the customer’s site in the Dahei region. This 2,000 m 3 /h capacity unit provides SRF with a continuously reliable nitrogen supply, with enhanced safety conditions, and also meet its need for autonomy. And at a cost that is significantly more competitive than the market price. Air Liquide’s success in this project illustrates the advantages of on-site gas production which has steadily increased, a growth particularly driven by China and the United States. After a record year in 2019 with 40 on-site production contracts, the Group signed 45 new contracts in 2020. In addition to the sales stability provided by these 10 to 15 year long-term agreements, they also help to reduce the Group’s carbon footprint as there is no gas to liquefy or transport to the customer, resulting in less CO2 emissions. For industrial companies, these on-site gas production solutions mean autonomy, reliability as well as being environmentally friendly. Ultimately, on-site gas production solutions offer flexibility and competitiveness.

“If the sales of on-site production units continue to grow, it is because they fully meet our customers’ new requirements: the need for competitiveness and the reduction of CO2 emissions. It also shows that our customers recognize our technological expertise in this field.

”

Matthieu Giard

Member of the Air Liquide Executive Committee and Vice President, Industrial Merchant business line

Digital technology providing greater proactivity

Competitiveness that the Group wants to further strengthen using digital technologies. Air Liquide is experiencing profound change thanks to digital technology, which drives performance and innovation. Digital technology powers the Group’s working methods at all levels of the organization. It now permeates the solutions provided to customers, such as the Integrated Bulk Operations program that has been rolled out worldwide. Air Liquide’s ambition is to improve customer service by optimizing the liquid gas supply chain end-to-end, using digital technologies and mass data collection from the production site to the customer’s site.

This solution has already proven itself in North America, where Air Liquide Canada has become a pioneer in the field. The entity now has 95% of its assets connected and already operates two-thirds of its liquid gas business using these technologies. How does it work? Customer consumption and molecule availability data are analyzed in-depth and driver routes are optimized, all in real time. This also has several advantages: the logistics teams anticipate customer requests, identify the most competitive molecules and adapt them to customers’ needs, in order to organize more efficient and reliable delivery rounds. The supply chain becomes more agile and CO2 emissions are reduced.

This program is based on four principles: predictive customer demand analysis, gas supply optimization, more efficient management of truck routes and real-time information on customer deliveries. The digital connection of supply chain assets – from production sites to trucks to customers’ on-site tanks – enables data reporting and analysis to improve the customer experience, operating performance and carbon footprint. A logistics revolution for the liquid gas business, which generates 27% of Industrial Merchant activity revenue (8,959 million euros in 2020) and supplies a variety of markets such as food, electronics, glass and metals industries.

Continuing strategic investments

This same quest to drive performance for its customers has led Air Liquide, despite the crisis context, to continue its strategic investments in several regions. In the United States, for example, the Group has strengthened its positions in Texas with the conclusion of long-term contracts with Eastman Chemical Company and Steel Dynamics, two of the region's major players, specialized in steel and chemicals. These contracts cover the supply of oxygen, nitrogen and argon to these customers thanks to the construction of state-of-the art and energy efficient air separation units (ASU). Air Liquide has also invested in Europe, where it has signed several long-term agreements with BASF, a world leader in chemicals, thus strengthening its strategic positioning in the Antwerp industrial basin in Belgium. The Group has also reinforced its industrial presence in Russia and Poland through long-term partnerships with steel producer NLMK and copper and silver manufacturer KGHM Polska Miedź. In China, Air Liquide continues its development with the construction of a new ASU in the port area of Tianjin, which will allow the Group to support the growth of the region's industrial players. These investments underline Air Liquide's commitment to support its major customers in their transition to safer, more reliable and sustainable technological solutions. They also demonstrate the Group's confidence in the growth of the industry and its transition to cleaner and more efficient methods of production.

The search for quality, reliability and performance, the need for supply autonomy, reduction of environmental impact… By working ever more closely with manufacturers and listening to their needs, the Group is inventing with them more efficient solutions.

Industrial gases is an historical core business for Air Liquide. This activity is organized in two business lines: the Large Industries business line serves customers in the metals, chemicals, refining and energy sectors. It supplies them with gas and energy solutions for their industrial production, solutions which are designed to improve the efficiency of the processes and the environmental footprint of their plants. Meanwhile, the Industrial Merchant business line provides comprehensive gas solutions to a wide range of customers – craftsmen, SMEs, large companies – in sectors as diverse as food, the pharmaceutical industry, aeronautics and automotive construction.