Supercritical CO₂: cleaner, safer and more competitive

Published on July 09, 2020

4 minutes

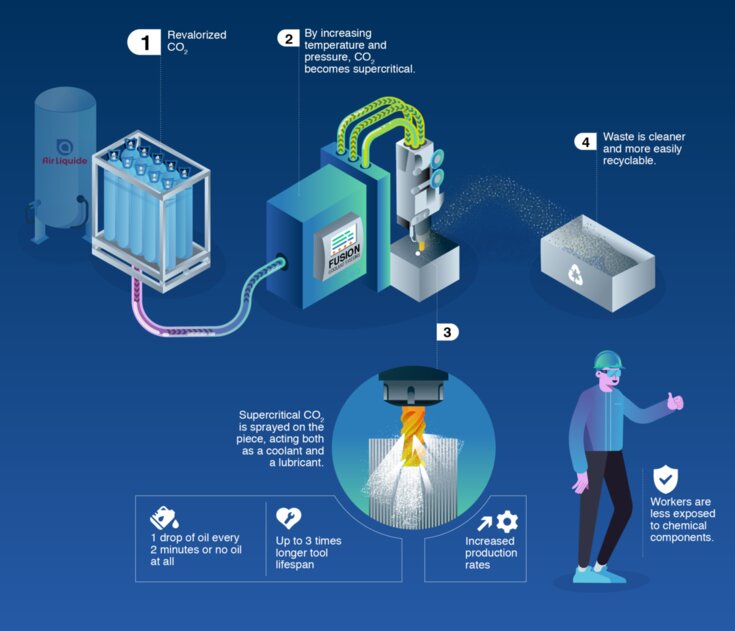

Air Liquide and the US-based company Fusion Coolant Systems have partnered to provide a breakthrough innovation for the machining industry based on supercritical CO2.Totally unique on the market, the “Pure Cut” solution enhances performance, productivity, worker safety and sustainability.

Always on the lookout for innovative technologies, Air Liquide sees the supercritical CO2 “Pure Cut” solution developed by Fusion Coolant Systems as a game-changer in the machining sector. In a unique promotion partnership, each company promotes the other to potential customers.

A supercritical fluid is a substance held at a temperature and pressure above its critical point, in a ‘fourth’ phase: not a distinct solid, liquid or gas, but with properties between a gas and a liquid. Carbon dioxide becomes supercritical at a pressure of 74 bars and a temperature of 31°C, a phase in which it can pass through solids like a gas, but dissolve materials like a liquid. This makes supercritical CO2 an effective solvent that is currently used in a variety of applications, from the decaffeination of coffee beans through the production of essential oils and pharmaceuticals to the cleaning of microprocessors. Its properties also make it a cutting-edge new cooling and lubrication solution for machine tooling.

Going supercritical

In machining – cutting raw materials into parts of a specific shape and size – heat management is critical. High temperatures due to friction during cutting are a principal cause of tool failure, can slow cutting speeds, and can cause imperfections in the finished product. A range of coolant options exist, including traditional oil-based lubricants, oil and water emulsions and, more recently, cryogenic solutions such as liquid nitrogen and liquid carbon dioxide, all of which have trade-offs.

In 2003, Steven Skerlos, who is today Chief Technology Officer of Fusion Coolant Systems, was looking for cleaner machining solutions and had the brainstorm that supercritical carbon dioxide (sCO2) would be an ideal cutting fluid. When he started testing the idea, he was surprised to find that not only was the solution cleaner, it actually improved operational performance. “The supercritical state means nano-sized droplets can get into the cutting area in a way that other solutions can’t, in a more consistent stream, and without damaging the spindle, tool or workpiece,” he explains.

After over a decade of development, he launched "Pure Cut", a patented sCO2-based cooling technology that can be used for any type of material – metals, carbon fibre, reinforced plastic, polyethylene – and can be easily integrated into existing machining systems.

A pure advantage

A world first, “Pure Cut” offers a number of benefits. The higher lubricity and cooling sCO2 provides allows higher productivity: depending on the material and process, it can increase machining speed by two to five times. The same properties also protect expensive cutting tools, extending their life by up to three times. Additionally, the quality of the machined parts is improved, as sCO2 enables a more precise surface finish.

Super-sustainable

The "Pure Cut" solution also has considerable benefits for workers and the environment. “As sCO2 inherently provides lubricity, it allows zero or minimal amounts of regular lubricants to be used in machining – and if lubricants are used, they are dissolved in the sCO2,” continues Steve Skerlos. For workers, this means no exposure to lubricants on the floor, in the air, or in contact with the skin, eliminating health concerns linked to traditional cutting fluids. It also means clean, oil-free waste chips that can be recycled more easily, and no polluted wastewater to treat. Air Liquide is also committed with its customers to working towards a clean and sustainable industry by proposing technologies which allow them to reduce or reuse their CO2 emissions. As such, the CO2 is recycled from other industrial processes and purified to give it a second life. The technology offers industry a sustainable, low waste alternative to traditional machining practices.

Partners in green machining

Convinced of Pure Cut’s promise, in 2020 Air Liquide signed a partnership with Fusion Coolant Systems in which each company will approach potential customers to offer this new technology in a comprehensive package. Jean-Marie Padovani, Director of Innovation Projects for the Industrial Merchant activities at Air Liquide during the signing phase, says: “This extends our portfolio with a pioneering solution that improves operating performance and reduces environmental impact for industries that represent a new market for us.”

For Air Liquide, the partnership opens opportunities for new customers as machining companies using standard liquid coolants switch to sCO2. Initially, the focus is on sectors with large volumes of difficult-to-machine metals, such as the medical, aeronautic, and automobile sectors, starting in France, Spain, Portugal and Italy.

Support from an expert

Brian Ahlborn, Fusion Coolant Systems CEO, concludes: “We’re a young company, so having a partner that is an expert in industrial gases and in installing failsafe systems gives our customers confidence that we’re linked with the world’s most professional firm in this area. They know they will be getting their questions answered by experts.”