Did you know? Air Liquide is 119 years old!

Published on October 07, 2021

3 minutes

How has Air Liquide grown around the world? How fast did it grow? When did the Group start contributing to the space industry? In this Q&A featuring anecdotes and key figures, you’ll learn more about Air Liquide and its nearly 120-year history.

How fast was Air Liquide’s international growth?

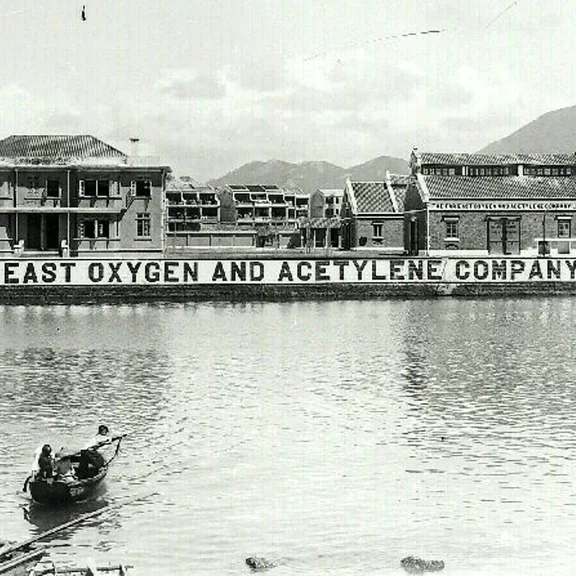

Soon after it was founded in 1902, Air Liquide set its sights on the international market.

The company expanded into Japan in 1907, and around Europe with its arrival in Italy and Spain in 1909 for instance. It then established units in Canada in 1911, followed by the United States in 1916.

The reason for this development is simple: Gas, by its very nature, is difficult to transport and thus local production is required.

The company expanded into Japan in 1907, and around Europe with its arrival in Italy and Spain in 1909 for instance. It then established units in Canada in 1911, followed by the United States in 1916.

The reason for this development is simple: Gas, by its very nature, is difficult to transport and thus local production is required.

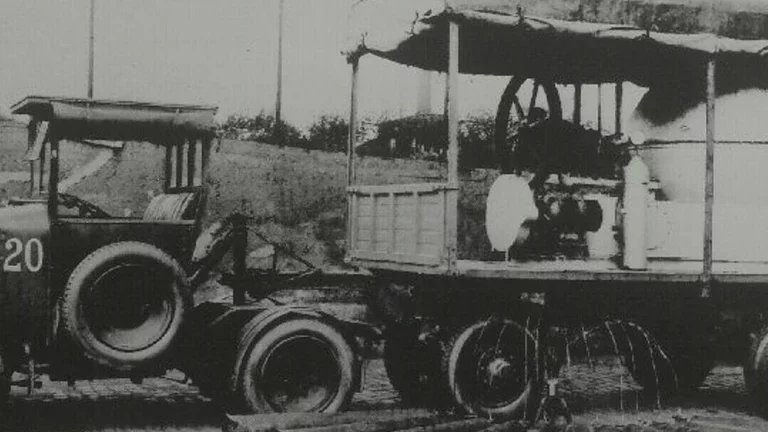

When did Air Liquide start building its gas pipeline network?

The first European gas pipeline was built by Air Liquide in 1925 in Turin, Italy, in order to supply Fiat’s automobile plants.

The idea of building a large-scale strategic gas pipeline network was conceived in 1960, connecting Air Liquide’s production plants together in order to better meet customer needs.

Today, Air Liquide manages more than 9,400 km (5,800 miles) of pipelines worldwide.

The idea of building a large-scale strategic gas pipeline network was conceived in 1960, connecting Air Liquide’s production plants together in order to better meet customer needs.

Today, Air Liquide manages more than 9,400 km (5,800 miles) of pipelines worldwide.

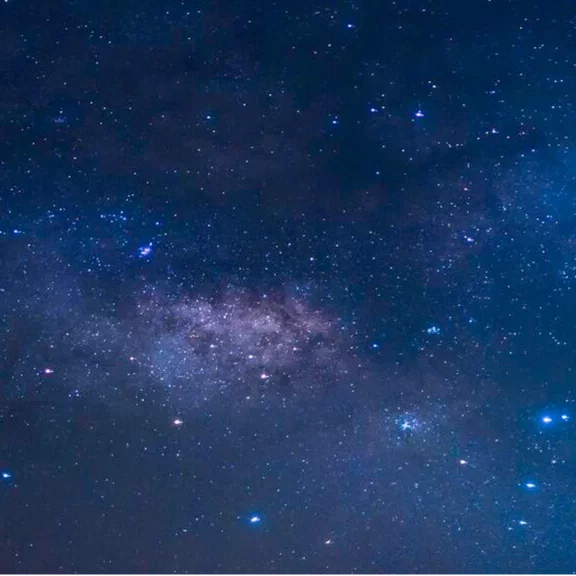

When did Air Liquide start supporting space exploration?

Jean Delorme, the then Chairman and CEO of Air Liquide, strongly believed in the market potential of cryogenics and decided to set up an advanced research hub dedicated to this technology near Grenoble, France, in 1962.

As a result, since the 1973 launch of the European Ariane launcher program in Brussels, Air Liquide has contributed to all iterations of the launcher — from Ariane 1 to Ariane 5.

The Group supplies the propulsion fluids—liquid oxygen and hydrogen—used for launches, and leverages its expertise in cryogenics.

As a result, since the 1973 launch of the European Ariane launcher program in Brussels, Air Liquide has contributed to all iterations of the launcher — from Ariane 1 to Ariane 5.

The Group supplies the propulsion fluids—liquid oxygen and hydrogen—used for launches, and leverages its expertise in cryogenics.

Who developed MELFI, Thomas Pesquet’s favorite freezer?

MELFI, the nitrogen-powered freezer onboard the International Space Station used for storing samples, was developed by Air Liquide.

MELFI turned 15 years old this year and received a happy birthday tweet from French astronaut Thomas Pesquet.

MELFI turned 15 years old this year and received a happy birthday tweet from French astronaut Thomas Pesquet.

How many of the latest smartphone models contain components, chips and storage devices, built using Air Liquide advanced materials?

All of them! Let’s take a step back in time: In the 1980s, the electronics market emerged, and Japan took the reins as market leader at the time. So in 1987, Air Liquide unveiled its laboratory in Tsukuba, Japan.

This center specializes in supplying ultra-high purity gases to the semi-conductor industry. These include carrier gases, mainly nitrogen, which allow for transporting specialty gases and keeping chip production tools inert, but also specialty gases used directly for manufacturing semi-conductors.

Since then, the Group has continually supported leaders in this sector, especially recently with its enScribeTM range of advanced materials.

This center specializes in supplying ultra-high purity gases to the semi-conductor industry. These include carrier gases, mainly nitrogen, which allow for transporting specialty gases and keeping chip production tools inert, but also specialty gases used directly for manufacturing semi-conductors.

Since then, the Group has continually supported leaders in this sector, especially recently with its enScribeTM range of advanced materials.