Engineering & Technologies

Delivering the future, today

Deploying a century of deep expertise and innovation, Air Liquide turns ambitious ideas into reality. Our innovations and technologies drive progress, advance industries, boost semiconductors, and enable the energy transition. Our people turn global challenges into opportunities. We deliver solutions that create real and lasting impact for our customers and society at large.

Delivering innovation

Our Engineering & Technologies (E&T) activity brings together Air Liquide’s expertise in technology, engineering, construction and project development and execution, to design and deliver cutting-edge industrial solutions.

With its unique portfolio of technologies and expertise, E&T offers a wide range of solutions to accompany the growth and meet the evolving needs of our customers, from the design of industrial gas production units to the manufacture of cryogenic equipment for space and energy applications, as well as low-carbon technologies such as electrolyzers and CO₂ capture solution or technologies for the semiconductor industry.

Developing solutions to decarbonize the industry

Breakthrough solutions for deep tech

Scientific research

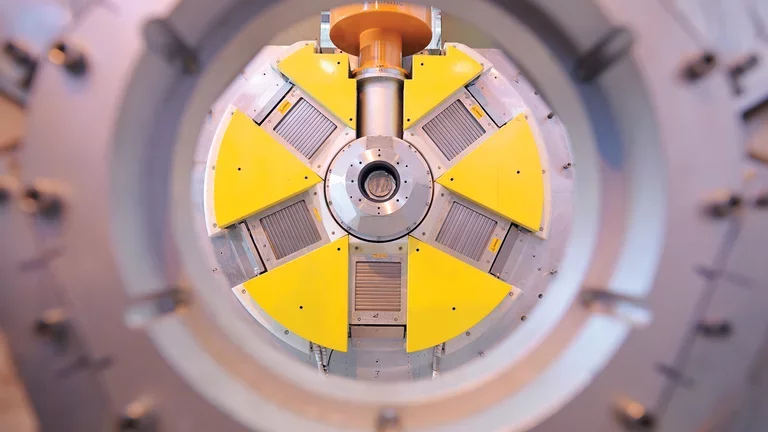

We support major scientific partners and projects, including in the fields of fusion power and quantum computing, with our expertise in mechanical cold production, gas liquefaction and storage and distribution of cryogenic fluids at extremely low temperatures.

Space

Our expertise includes launch pad infrastructure, on-board cryogenics, and ground test equipment for launchers and satellites. We also develop energy production and storage technologies, as well as air purification equipment, to support space exploration.