Digital technologies are key to optimizing the entire bulk supply chain. They enable more efficient, reliable and energy-efficient delivery rounds thanks, among other things, to the analysis of customer data and real-time driver assistance. For employees in the field, they are also a source of efficiency and therefore peace of mind. With this objective in mind, the "Integrated Bulk Operations" (IBO) digitization program was launched in 2017.

Offering the best daily service

Every day around the world, Air Liquide's trucks travel over 1 million kilometers to deliver liquid gases, which is the distance from the earth to the moon and back. Every day, 4,000 drivers, 250 dispatchers and 50 business leaders work hand in hand to guarantee that our customers receive the right products, on time and safely.

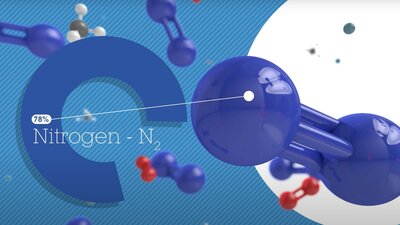

These people work all along Air Liquide's Bulk value chain. The activity is responsible for transporting bulk gases from our production units to the points of consumption, at customers' sites, and also to Industrial Merchant and Healthcare filling centers, which then serve our customers with gas in cylinders.

The Canadian example

With 95% of their assets connected (connected equipment on trucks, telemetry on customer installations), the country is already operating two-thirds of its Bulk business digitally.

“The IBO program has enabled us to make a real leap forward in terms of performance, customer experience and environmental footprint. It also brings real peace of mind for our employees in the field.

”

Eric Lalonde

Vice President, Operations, Process Industries, Bulk Activity, Air Liquide Canada

Key figures in Canada

90% of the 2,000 customer tanks are connected

100% of 150 trucks are connected

18 million kilometers traveled per year

In addition to transporting and delivering goods, the driver is also in charge of loading trailers, inspecting the fleet, entering the loaded volumes, sending delivery notes to customers... The digitization of operations has really eased his daily life.

“The digital management of transactions and the reporting of risky situations are done in real time through the tablet. It helps me to be more efficient and the risk of error is close to none

”

Alain Legros

Air Liquide driver in Varennes, Québec

“As part of the IBO program, we use a software which helps me make more efficient trips. Based on customer needs and available resources, this system performs calculations and suggests the most efficient and practical bulk delivery trips.

”

Vanessa Tissot

Dispatcher, Air Liquide Canada

A worldwide deployment

After a successful pilot phase in 5 geographical areas - Canada, the United States, France, Germany and China - the Group is rolling out the IBO program worldwide.

This way Air Liquide further accelerate its digital transformation for an always better customer experience.