Tackling climate change challenges requires strong and collective action. Not only is Air Liquide committed to reducing CO2 emissions from its own operations, but we are also helping customers decarbonize at the same time. In close collaboration with industrial partners, we are increasing our involvement in a variety of large-scale clean energy solutions, such as low-carbon hydrogen production and supply, carbon capture and storage technologies and biomethane solutions. Our ambition is to act as the leader of industrial decarbonization.

-33% reduction in Air Liquide's absolute-value carbon emissions by 2035

€8 Bn will be invested in the low-carbon hydrogen supply chain by 2035

Foster

“Air Liquide is a leader in hydrogen and we are committed to investing €8 billion in the low-carbon hydrogen supply chain by 2035.

”

Matthieu Giard

Member of the Air Liquide Executive Committee and Vice President supervising Hydrogen and Industrial Merchant activities

What makes hydrogen a solution for decarbonizing industry and heavy transport?

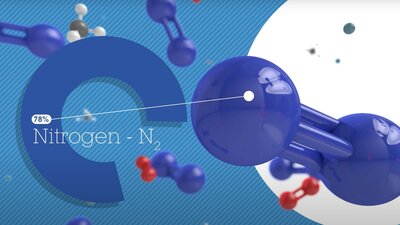

Hydrogen plays a key role in the energy transition, particularly when it comes to decarbonizing industry and heavy transport, which represent 18% and 25% of worldwide CO2 emissions respectively1. Air Liquide has 50 years of expertise in hydrogen, and 20 years ago we banked on the molecule being used for clean mobility. Since 2021, things have rapidly accelerated. More than 30 governments have positioned hydrogen at the heart of their energy strategy, with 100 billion euros2 pledged in support of its large-scale roll-out. By 2050, it is expected to account for more than 20% of global end-use energy demand3.

As a pioneering group in the hydrogen sector, how can Air Liquide accelerate this roll-out?

The entire hydrogen ecosystem is in development! We firmly believe that when it comes to tackling environmental challenges, we are all in this together. In this ramp-up phase, we are forging strategic partnerships with industry and transport stakeholders including TotalEnergies, Siemens Energy, BASF, Airbus and Faurecia4, to create industrial projects and infrastructures for the production and distribution of hydrogen. To accelerate our efforts alongside our industrial and financial partners, we have created the largest global fund fully dedicated to expanding hydrogen infrastructure, funded with 1.5 billion euros. In the face of climate change, it is crucial that we combine technologies, expertise, and industrial and financial capabilities to accelerate the production and use of low-carbon hydrogen.

What do you think the development of hydrogen will look like in 10 years?

The hydrogen revolution is already underway. Today, we need to boost its roll-out by leveraging the commitments made by public and private sector players to achieve carbon neutrality by 2050. We are going to invest 8 billion euros in the low-carbon hydrogen supply chain. Our strategic investments in large-scale electrolyzers, such as those we have already made in Canada, France and Germany, will bring our overall electrolysis capacity to 3 GW by 2030 for producing renewable hydrogen. The decade of hydrogen has begun, and it is our ambition to act as a hydrogen leader.

“The maturity of our portfolio of carbon capture and storage solutions and our expertise give us legitimacy in contributing to the decarbonization of industry.

”

Cristina Ballester

Vice President Large Industries Europe, Air Liquide

Why is carbon capture and storage (CCS) considered an essential lever to reach carbon neutrality by 2050?

While society is accelerating the usage of renewable energy to address climate urgency, we also need solutions that will support the transition by enabling the capture of large volumes of CO2 emitted by industrial actors. This avoids emissions in the short term, particularly from industries whose emissions are hard to abate, such as cement, steel and chemicals. In these sectors, CCS is an effective and viable solution for industrial processes that don’t yet have alternatives.

How is Air Liquide answering this challenge?

We have been developing carbon management solutions for 15 years. Our CryocapTM CCS solution uses cryogenics technology to capture CO2. The process is highly efficient compared to solvent-based technologies, recovering up to 98% of CO2. CryocapTM is part of a full carbon capture service offer we are currently developing that will include CO2 capture, purification, liquefaction, storage and transport to the sequestration site. In some cases, we also recycle the CO2 for other uses (carbonation of sparkling beverages, food preservation and freezing, etc.). The maturity of our solutions portfolio and our expertise give us legitimacy in this key growth area that is crucial to reducing industrial carbon footprints. Our customers know they can rely on us for performance, reliability, safety and supply continuity.

Do you have some recent concrete examples to illustrate this?

We have several projects underway in Europe. For example, in the industrial basin of Dunkirk (France), we are developing projects with Lhoist and EQIOM to capture their CO2 emissions. These partnerships aim to create a low-carbon industrial ecosystem in the wider Dunkirk area. In Normandy, France, and Zeeland, the Netherlands, we’re implementing large-scale CCS solutions at hydrogen production units in collaboration with TotalEnergies. With BASF in Antwerp, Belgium, we’re planning to develop the world’s largest cross-border CCS value chain. The Kairos@C project won support from the European Innovation Fund, confirming the efficiency of our technology, which an increasing amount of industries will need to reach carbon neutrality.

Achieve

Invent

Air Liquide firmly believes that hydrogen is the key to accelerating the energy transition. The Group is partnering with major players from various sectors who offer complementary skills to harness the full potential of hydrogen, from production to future distribution methods. This generates a reduction in industrial CO2 emissions and an increase in the development of clean transportation.

Decarbonized industry

Air Liquide and Siemens Energy have joined forces to create a European ecosystem of hydrogen production technologies by electrolysis, thereby promoting the emergence of a sustainable hydrogen economy in Europe. One of the large projects backed by the French and German authorities is the construction of a renewable hydrogen production unit with a capacity of 30 MW in Oberhausen, Germany. This industrial-sized unit will be the first of its kind to be connected to the existing Air Liquide pipeline network.

The future of aviation

Sustainable transport

2. 2021 reports from the Hydrogen Council.

3. Idem.

4. Now known as Forvia.

5. PEM: Proton Exchange Membrane.

6. Aéroports de Paris, a global leader in airport design, construction and operation

7. Now known as Forvia.