As the first and only gas company to offer an in-house craft beer expertise, Air Liquide, through its U.S. subsidiary Airgas, supports the bubbling American craft beer market. We met with Dan Peterson, Brewmaster & Director of Operations at Ferment Brewing Company.

Riding the wave

According to the Brewers’ Association, there were an estimated 7,346 craft breweries in the U.S. at the end of 2018, including more than 4,500 microbreweries and more than 2,500 brewpubs. It was on this seemingly unstoppable wave that Dan Peterson hatched his idea to open a craft brewery in August 2018 in the small town of Hood River located 60 miles east of Portland, Oregon.

After their first meeting a year and a half ago, Joe helped him immediately with the planning of his gas supply needs.

“You just know you’re talking to a beer specialist as much as a gas specialist. We talk about the latest craft beer conferences and I like to discuss the new beers I’m planning and listen to his advice,” Dan says.

Reliable and personalized gas supplies

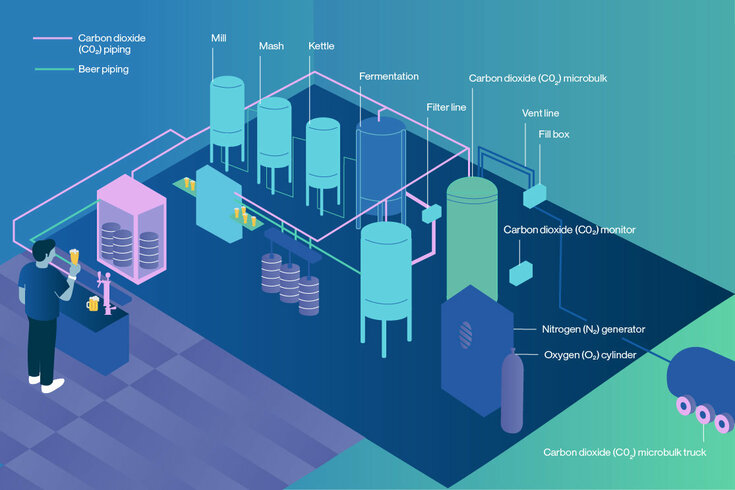

Airgas provides Dan with carbon dioxide (CO2), the imperative brewing gas which, in addition to carbonation (see diagram below), he uses to purge kegs and bottles before filling, push the beer from fermenter to keg, and propel the beer from keg to glass when it is served in the brewery’s tasting room. Ferment’s outdoor 1,000-lb CO2 tank is refilled every two or three weeks with liquid gas at - 50°F (- 45°C). Dan explains: “we use that 120 psi CO2 (unit of pressure or of stress) for production and serving from our draft cooler”. In addition to CO2, Dan buys oxygen, which he uses to develop yeasts, and nitrogen, specifically to create the recognizable “cascading” effect when serving his dry stout – think of a famous black Irish beverage, and you’ll get the picture.

With production currently standing at 800 to 1,000 barrels (or 31 gallons / 140 litres) per year, Ferment is looking confidently to the future. “We are aiming to ramp up steadily and get out into other markets,” says Dan. “We just took delivery of two 40 barrel fermenters which ought to help us double our production by the end of 2019.” With no signs of the craft beer market slowing down, there’s nothing to stop a beer fan like Dan from stepping on the gas.

Airgas, a beer expert

With a long experience in the brewing industry and in beer dispensing, Air Liquide helps craft brewers maximize productivity and reduce downtime with more effective gas and equipment supply chain management, simplified gas system maintenance, and expert safety solutions all backed with uncompromising customer support. Airgas, Air Liquide’s subsidiary in the US, offers comprehensive solutions tailored to brewers’ needs with the help of its technical experts who notably provide gas consulting services and gas consumption monitoring. Serving customers through more than 1,400 locations, Airgas takes care of brewers’ products throughout the beer value chain and assists them in managing their facilities.

Dan Peterson, a beer professional thriving on flavor diversity

Carbonation is quite simply the addition of carbon dioxide to a liquid to make it fizz. Beer already contains a small amount of gas due to natural fermentation occurring during the brewing process, but the majority of brewers still carbonate their beer with CO2. “This helps to create the head (the foam on the top of the beer in a glass), nose (liberating the aromas of hops and malt) and mouthfeel,” explains Joe Keller, Craft Applications Specialist at Airgas National Carbonation.

Carbonation is no simple task and requires patient and careful testing. “Carbonation brings the beer to life,” says Dan Peterson at Ferment. “I’m always trying new quantities of CO2 in my new recipes to get the right aromatics so that the beer can express its full character.”