Cutting-edge technologies for low-carbon production

Published on March 27, 2024

3 minutes

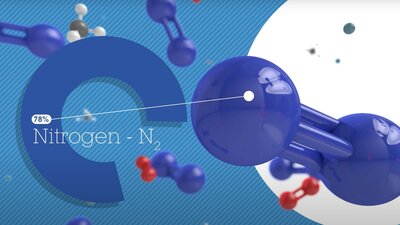

Air Liquide is firmly committed to decarbonizing its own production methods, with the aim of significantly lowering its CO2 emissions by 2025 and reducing them by a third by 2035(1). The Group is therefore developing solutions to improve the industrial and energy efficiency of its Air Separation Units (ASUs) and its low-carbon hydrogen production processes.

More efficient Air Separation Units

In the Tianjin basin in China, Air Liquide has operated four ASUs supplying industrial gases to the healthcare and industrial sectors for more than 20 years. In 2023, the Group invested 60 million euros in a transformation project to reduce the carbon footprint of two of these ASUs, as part of a long-term contract with Tianjin Bohua Yongli Chemical Industry Co., Ltd. The aim is to adapt these plants to run on electricity instead of steam, thereby reducing annual CO2 emissions by 370,000 tonnes. This is equivalent to the electricity-related emissions of more than one million Chinese households.

Toward very large-scale, low-carbon hydrogen production

Air Liquide has also established itself as a leader in autothermal reforming (ATR) technology, an efficient large-scale solution to produce low-carbon hydrogen, with 70 years of experience. When ATR is combined with carbon capture technology, it can achieve higher energy efficiency with lower investments and a simplified production process to facilitate the capture of up to 99% of CO2 emissions in highly integrated industrial facilities. The Group will use this technology as part of a pilot project with INPEX Corporation, a Japanese energy company, to produce low-carbon hydrogen and ammonia.

At the same time, Air Liquide is working with KBR to develop technological solutions integrating the ATR process to produce low-carbon ammonia and low-carbon hydrogen. The solutions provided will contribute to the development of a global low-carbon hydrogen market as hydrogen, when transformed into ammonia, can be easily transported over long distances.

In addition, the Group is building an ammonia cracking pilot unit in Antwerp in Belgium, using innovative technology to transform ammonia into hydrogen with a reduced environmental impact. This initiative will make it easier to transport hydrogen and contribute to the development of hydrogen as a key enabler of the energy transition.

"I firmly believe that technology will play a key role in the decarbonization of industry and mobility. That’s why we keep developing solutions that address our customers’ environmental challenges as well as our own climate objectives. Not only do we have the right technologies, but our teams have the skills and the execution capabilities to deliver them.”

Philippe Merino

Group Vice President supervising Engineering & Construction at Air Liquide