Hydrogen, an alternative to reduce the carbon footprint of the glass industry

Published on September 13, 2024

2 minutes

Accompanying glass manufacturers towards a low-carbon production is one of Air Liquide’s challenges. As part of their research on hydrogen combustion for glass manufacturing, the Group’s R&D teams conduct tests under real operating conditions. The latest of these tests were conducted in collaboration with SGD Pharma, a company that manufactures glass containers for the pharmaceutical industry, in its factory in Saint-Quentin-Lamotte, in northern France. Find out more in our video.

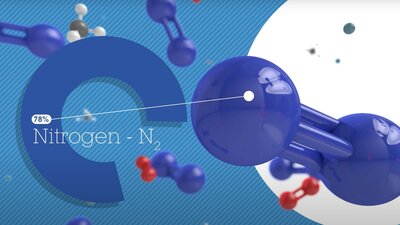

Reducing the carbon footprint of the glass industry, which is a particularly energy-intensive sector: that was the goal of the tests conducted in February 2024 by Air Liquide and SGD Pharma. Glass is made by melting a mixture of silica (contained in sand) or recycled glass – and this requires very high temperatures of around 1,400°C. When used as a combustible instead of natural gas, hydrogen can be an alternative for decarbonization since, during its combustion, it combines with oxygen to only form water vapor. So there is zero emission of greenhouse gases. As a comparison, during the combustion of one cubic meter of methane, about 2.5 kg of CO2eq is emitted.

Moreover, when it is produced from renewable electricity, the environmental footprint of hydrogen is even smaller.

“More than one third of CO₂ emissions in glass production result from combustion. Hydrogen is a very promising alternative, because when burned, all you get is water, no CO₂.

”

Anna-Maria Pubill-Melsiо́

Manager of the team R&D Combustion at Air Liquide

Hydrogen is one of the solutions to decarbonize hard-to-abate industries. By 2050, according to a study by the Hydrogen Council, hydrogen could cover 20 to 25% of the energy needs of industrial processes that require high temperatures.

The tests conducted by Air Liquide for SGD Pharma have shown that up to 50% of natural gas can be replaced with hydrogen without altering the quality of glass while maintaining the industrial performance of the furnace. Next step: testing a 100% hydrogen combustion. These very positive first tests confirm that hydrogen is a promising alternative for decarbonized glass manufacturing.

Thanks to these successful tests, Air Liquide positions itself as a strong partner for this decarbonization.

“Air Liquide has been supporting its customers for many years to replace air with pure oxygen in their furnaces in order to improve energy efficiency and to reduce atmospheric emissions.

”

Jean Caudal

International Combustion Expert, R&D Project Coordinator at Air Liquide