As the 5th edition of the VivaTech exhibition should have taken place from 11 to 13 June in Paris, we wanted to come back with you on the digital transformation of the industry, a major theme for Air Liquide.

Since our creation in 1902, industrial gases have been at the core of our business. In 80 countries, we currently supply more than 2 million customers in the industrial sector. And in this digital era, we are working to improve our operational excellence and to better meet the needs of our customers, while supporting them in their transformation.

Data to improve industrial efficiency

As part of our “Smart & Innovative Operations” program (SIO), we have introduced a predictive maintenance system to improve the reliability of 200 of our production sites. This program also optimizes the energy consumption of our sites using data collected each day and the human intelligence of our operators and big data experts.

1 billion: this is the number of data that we collect each day using sensors at our production facilities.

The view of Bruno Aïdan

Chief Data Officer of Air Liquide

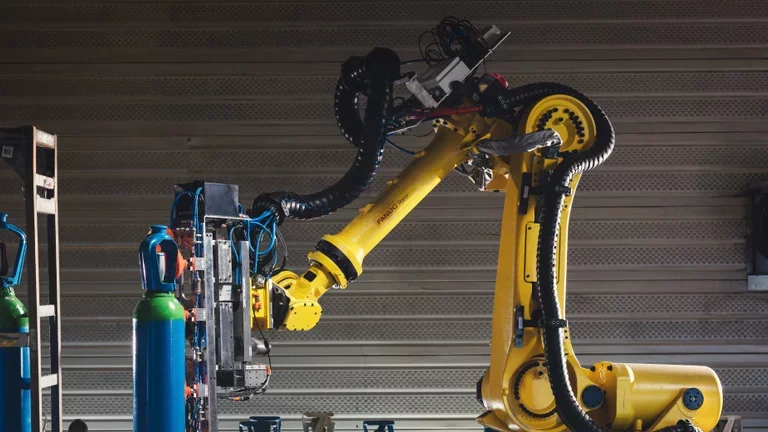

Modernized packaging centers

Our teams are also working on robotization projects. The aim: modernizing our gas filling centers to optimize delivery times for customers and facilitate their lives, from the order intake through to delivery. At the end of 2019, we thus inaugurated our first robotized cylinder gas order preparation unit in Feyzin, near Lyon. The handling of cylinders is made easier and deliveries are optimized with next-day delivery from the moment an order is received. This modernization program will be rolled out until 2023 across our three largest French filling sites.

New range of innovative solutions

We also innovate to meet the requirements of our welding customers, who often work in highly competitive markets and must manage several factors. Therefore, after working in collaboration with more than 700 welding customers, we created Qlixbi. This offer includes a new generation of gas cylinder, which is safer and more practical, as well as a range of digital solutions which help them manage inventories and facilitate team work thanks to a dedicated application. The welding experience is therefore transformed and simplified.

+700: this is the number of customers who took part in the creation of Qlixbi, the new revolutionary solution for welders.