Air Liquide has received a prestigious Red Dot Design Award for its Qlixbi packaged gas offer. What was it about this system for supplying welders with gas cylinders that caught the jury’s attention? What is unique about this new solution? We went behind the scenes to meet the people involved in the design process from the start.

“During the trialling phase, there was this one session at a distribution center in United Kingdom,” recalls Sylvestre Coulon, “when we had the first iteration of the design that really looked like today’s Qlixbi – and one of the three test customers, quite a young chap, started to get really enthusiastic about the easy-to-read reserve indicator and the simple change connector. ‘If you just moved that part a bit down…’ he said, grabbing my arm and gesticulating. That was when I knew that we were really onto something.”

Making a product centered on customer usages

Sylvestre Coulon, Offer Manager at Air Liquide, has been involved in Qlixbi right from the start. Due to his hands-on role in the project, he is just the right person to explain the details of the revolutionary approach the company took to designing this packaged gas offer. “With Qlixbi, we wanted to apply the same methodology as in consumer goods or software development to industrial design. The rationale was that this would help us reduce the length of development cycles and, most importantly, make a product centered on customer usages.”

In total, 700 welders were involved in the design phase, with 30 test cycles taking place.

“It was a completely new way of developing an industrial product, but it really paid off. Welders are not the type of people to say nice things about a design for the sake of being polite,” adds Coulon with a knowing chuckle, “so the feedback they gave was honest – and therefore valuable.”

Before they were presented with the first prototypes, some of the welders had already received visits from the multidisciplinary Qlixbi team: sociologists were sent to carry out interviews and observe them at work. All in all, the project drew on a broad range of Air Liquide expertise, from packaged gas specialists with core product knowledge through to experts in user research, user experience (UX) and the Internet of Things (IoT). In another first for the segment, a design agency was commissioned at an early stage to bring in approaches from other industries and product categories. It was key for Air Liquide to be able to offer a simple, aesthetic, and efficient product to its existing clients in traditional industries.

Meeting both technical and emotional expectations

"From a design perspective, there are three key areas," explains Matthieu Delapalme, Director of Pulp Design, the agency that helped Air Liquide in the process: “technical performance, ergonomic requirements, and aesthetic considerations. Air Liquide’s technical competence is unparalleled, of course,” says Delapalme, “so our role was to help improve the ergonomics – lightweight construction, easy handling, and functionality – and to rethink the aesthetics by creating a clear visual language for Qlixbi."

"Two things we identified during our preparatory work was welders’ deep pride in the ability to do a job well and a strong connection with objects and materials,” recounts Coulon. “Just because they work in industrial environments with all the dust, oil, and noise that entails, that doesn’t mean they don’t value aesthetics,” he adds. As such, the Qlixbi team worked on the hypothesis that, while a pleasing appearance would not be the key selling point for Qlixbi, it would strengthen customer loyalty in the long run. "What is more," says Coulon, "one way companies can attract and retain increasingly rare young welders is by providing working environments and products which respond to their expectations".

Creating a modern design is an expression of Air Liquide's commitment to welders

These expectations are increasingly shaped by companies with a strong design culture who have, in recent decades, transformed more or less utilitarian products into smooth, desirable, even beautiful objects. Beauty, though, is in the eye of the beholder and dependent on context, so the challenge for the Qlixbi team was to introduce design elements into the product which gave it a distinctive appearance and emotional content, yet did not belie its industrial purpose.

One element in play here was packaging. In classic industrial design, the wrapping materials in which products are shipped is rarely given much consideration. Qlixbi connectors, however, come in an attractive box containing simply illustrated instructions and information on how to access the full manual online. “This ‘welcome kit’, as we call it, both improves usability and helps reinforce the overall ‘wow factor’ – the feeling that this really is a product that was designed for them before being a technical tool.”

Three questions for Antoine Frenal, Design Office Manager :

What was your role in the Qlixbi project – and what was your experience of it?

I was involved at various stages of the project in different roles. At first, I helped design the technical basis of the product. Then when we got to the development and industrial stage, I managed materials and mechanical design team, and also liaised with the various suppliers and sub-contractors involved. My experience of Qlixbi was that it was a very different kind of project: we placed the user firmly at its centre, talked to potential customers about what a truly contemporary welding gas supply system would look like, and were able to repeatedly test various concepts for improved usability and aesthetics. I would also like to underline that all teams involved in this project have worked like one. This was a defining element of success.

How was this different to Air Liquide’s approach to design thus far? And what were the constants?

With Qlixbi, the technical basics remained unchanged, but due to the agile, iterative way of working, we had the opportunity to try out new looks, symbolic and emotional content, and ergonomic concepts on this technical framework. So rather than making one decision about how the product should look or feel and then sticking with it, we were able to test various options and see what was or wasn’t working. Essentially, we fused safe, secure, stable modules with new design elements.

Stage by stage, what does the Air Liquide design process look like for Qlixbi?

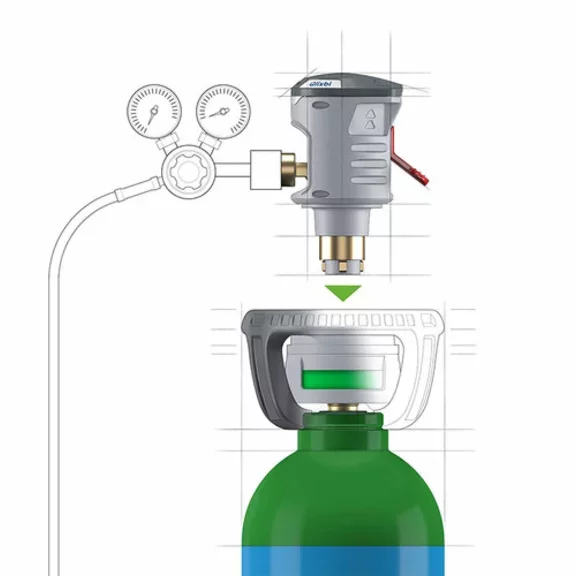

Like all designers, we always start with sketches – really quite rough early on. Once we have something we think will work, it goes into modeling: the first models are not particularly detailed, but are more about getting a feel for size, weight, and handling. We slowly work our way towards prototypes, testing functional elements and improving them. With connectors, for instance, that means making levers easier to feel and manipulate through the thick, heat-resistant gloves that welders wear. For Qlixbi, we took these prototyping and modelling methods and sped up the cycles, making them more flexible so that we could integrate feedback from beta tests into the next iteration.

The project also brought us a new technical challenge: integrating electronic components into the product in order to support its digital service component. One challenge was making sure that our product was heat-resistant and that electronic sensors and communications technology would be robust enough in view of the fact that their life-spans and maintenance cycles differ from those of metal cylinders and connectors. This added an electronic dimension to our mechanical design work – which, thanks to the broad range of expertise in the project, we mastered.

Qlixbi, not just a physical product

Another unique aspect of Qlixbi is that it is not just a physical product, but a system which unites a product and services. There is a Qlixbi app to help companies monitor their gas reserves, for instance; managers receive alerts when they need to reorder and can even use an auto restock function for complete peace of mind. “We worked closely with UX designers to make sure that the software interface is as intuitive and accessible as the cylinders and connectors,” says Coulon: “It’s easy to design something complicated, but far more difficult to make it simple.”

A wide range of people and expertise behind a success

"Since the beginning of the project, we’ve worked with a really wide range of professions and people. It’s been very enriching – and because there are always improvements which can be made, we’re not finished yet.” Isn’t he proud that the success of the project to date has been recognized with an award, though? “Sure, but winning a prize is one thing – watching the product enthuse the people who use it is the real reward.”