Renewable hydrogen: a gigafactory of electrolyzers to scale up

Published on March 29, 2024

3 minutes

An energy vector that currently meets just 3%(1) of the world’s needs could, by 2050, meet 20%(1) of the demand. This is the remarkable prospect for hydrogen, a potentially pivotal molecule in the energy transition. A hydrogen future depends on competitive, large-scale production of low-carbon hydrogen – and, therefore, a mass supply of electrolyzers: a production technology that uses electricity to separate purified water molecules (H2O) into hydrogen and oxygen.

Air Liquide is playing a leading role in the entirely new industrial and economic ecosystem needed to drive the future of hydrogen. We are partnering with major industrial and technology enterprises, including a joint venture with Siemens Energy. And these are not merely plans: 2023 ended with the inauguration of a world-first hydrogen gigafactory to produce large-scale PEM(2) electrolyzers.

On November 8, 2023, production began at the new Air Liquide Siemens Energy Joint Venture gigafactory in Berlin. The cutting-edge 2,000 m² plant, highly automated with robotics, is producing electrolysis stacks that use proton exchange membrane (PEM) technology.

Initial manufacturing capacity is 1 GW per year, with ramp-up plans targeting at least 3 GW per year of output by 2025. In terms of hydrogen production capacity, this would translate into 1,200 tonnes per day more of hydrogen. The project also builds on real-world knowledge from our operations to continuously hone and optimize the potential of mass-scale electrolyzers.

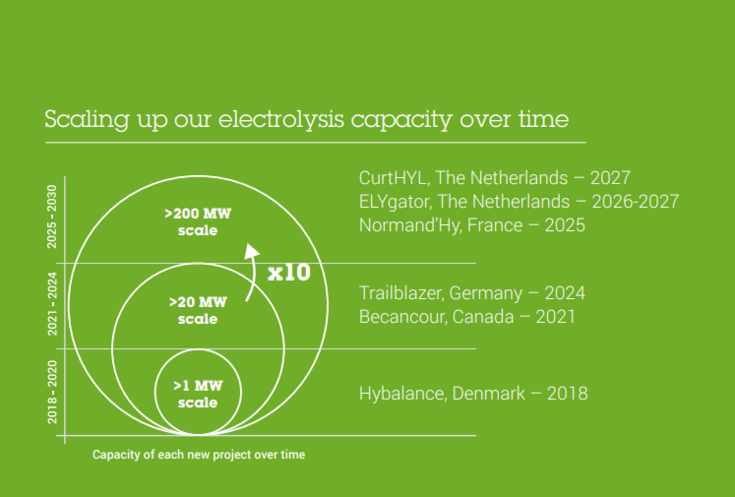

This strategic joint venture will equip a portfolio of current hydrogen projects, including notably:

- Our 20 MW hydrogen production unit in Oberhausen, Germany, contributing to accelerate the decarbonization of the Rhine-Ruhr industrial basin.

- The Normand’Hy project in Port-Jérôme, France, with a capacity of 200 MW – the largest PEM electrolyzer under construction, which will integrate equipment produced in the framework of the joint venture. It will avoid the emission of 250,000 tonnes of CO2 each year.

- In the Netherlands, two other large-scale electrolyzer facilities will provide low-carbon hydrogen to various industrial and mobility market customers. With individual capacities of 200 MW, these projects are set to collectively produce approximately 30,000 tonnes of low-carbon hydrogen annually, without generating CO2 emissions.

20% share of hydrogen in the world energy mix by 2050⁽¹⁾

3 GW Air Liquide's electrolysis capacity by 2030

250,000 tonnes of CO₂ will be avoided each year with the Normand’Hy electrolyzer

“This gigafactory is a decisive step forward in offering large volumes of renewable hydrogen to the industrial and mobility sectors. Production units equipped with PEM electrolyzers will contribute to decarbonizing these markets. The gigafactory also gives Air Liquide and Siemens Energy a significant advantage by ensuring privileged access to crucial equipment for successfully scaling up the production of renewable hydrogen.”

Marie-Khuny Khy

Director of Electrolysis Product Line at Air Liquide

(2) Proton Exchange Membrane.