Cleaner water through circular chemistry

Published on February 21, 2022

What if hazardous waste could be turned into a resource? An innovative technology developed by the Belgian scale-up Inopsys with expertise from Air Liquide uses a circular, sustainable process to give aqueous waste streams a second life, recuperating clean water and valuable raw materials.

Eco-friendly treatment of pharmaceutical waste

Ensuring fresh water access is an increasing global challenge. A variety of industrial processes generate complex waste streams containing a mixture of toxic organics, metals and active pharmaceutical ingredients (APIs) that are not easy to remove. Dealing with these streams most commonly involves shipping them off-site, sometimes over long distances, to be burned as waste—a carbon-intensive process that destroys both the water and the potentially valuable components it contains, such as metals (palladium, platinum, zinc, vanadium, etc.) and solvents.

To address this specific need and provide a more circular alternative, Air Liquide has both invested in and partnered with Inopsys, a Belgian scale-up that developed innovative technology to treat these waste streams without discharging hazardous materials into the environment. The two companies work together in an open innovation partnership, and have together designed a solution for a multinational pharmaceutical company's production facility in Belgium.

"While only trace levels of pharmaceuticals in the environment come from the production process, everyone’s goal is the highest level of purification possible," explains Ivan Pajolli, Global Marketing Manager of Air Liquide Utilities, Recycling & Waste. "The Inopsys solution uses a combination of three different technologies, resulting in significantly more effective decontamination compared to standard mono-technology. Inopsys’s hybrid technology has reduced the 20 APIs contained in the customer’s wastewater to less than 0.01 parts per billion, lower than the directives for predicted no-effect concentrations (PNEC)."

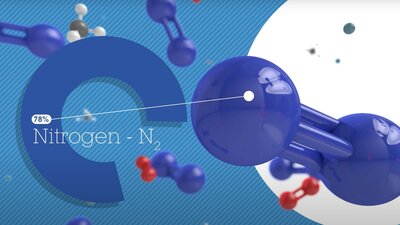

The central technology used is ozonolysis, which requires ozone (O3). Oxygen supplied by Air Liquide is the main raw material for this O3 production. "We partnered with Inopsys not just as a gas supplier, but our engineers were also involved in a joint R&D effort to achieve reliable O3 generation and dosage," continues Ivan Pajolli.

Energy-savings at a lower price

Another plus is that the technology reduces CO2 emissions. It requires less energy compared to standard processes, in addition to avoiding the transport and burning of waste. A modular, mobile unit, the solution is customized for the specific need and installed, operated and maintained on-site by Inopsys for the required period. This turnkey package aims to make it low-risk for companies to choose the technology over more costly and energy-consuming treatments or incineration.

Committed to fostering more sustainable and innovative processes, Air Liquide will continue to partner with Inopsys, helping them expand the scale of their technology to meet the water treatment needs of a range of industrial customers around the world.

Up to 1 ton of CO2 eq per 1m3 of wastewater treated

Up to 30% cost savings compared to incineration

Up to 99.99999% Selective removal of 23 APIs in one treatment

Interview with Steven De Laet, CEO of Inopsys

Wastewater streams from fine chemical and pharmaceutical production are very complex – it’s like a soup containing a large mixture of compounds. Not all of these are toxic or non-biodegradable. Our system uses a customized combination of technologies to allow highly selective degradation of certain compounds, for example, APIs, without degrading organic compounds that can be biologically treated in a wastewater treatment plant. While other technologies use a broad and destructive approach, ours specifically attacks only the problem-causing components. This hybrid solution results in more reliably clean water and uses less energy.

We met some experts from the ALTEC team (Air Liquide's network of experts in gas applications) and saw that we shared a vision of developing more efficient wastewater solutions. As for the pharmaceutical industry solution, we co-engineered the advanced oxidation processes technology using ozone. We also collaborated on the design of an application using CO2 to recover palladium. Other technologies we are developing will need nitrogen, so I see multiple synergies in the coming years that will require the supply, infrastructure and engineering of Air Liquide.

A growing global issue is micropollutants known as ‘forever chemicals’ – endocrine-disrupting chemicals, PFAS, etc. Some of these slip through wastewater treatment in very low concentrations, causing a chronic problem as they accumulate in the environment. There is increasing recognition of the need to further purify waste streams to remove these compounds. We are investing in R&D to develop innovative solutions for challenges such as this to help our customers get ready for future regulations.